Teach you how to use a pulsating vacuum sterilizer

The pulsating vacuum sterilizer is a commonly used sterilizer at present. Its operation steps are as follows:

1. The pulsation vacuum sterilizer must be placed on a solid horizontal surface.

2. Add an appropriate amount of water to the outer pot, put the items to be sterilized into the inner pot, cover the pot and tighten the screws symmetrically.

3. Heating causes steam to be generated in the pot. When the pointer of the pressure gauge reaches 33.78kPa, open the exhaust valve to discharge the cold air. At this time, the pointer of the pressure gauge drops. When the pointer drops to zero, close the exhaust valve.

4. Continue to heat, the steam in the pot increases, and the pressure gauge pointer rises again. When the pressure in the pot increases to the required pressure, reduce the firepower and maintain the steam pressure at the required pressure for a certain period of time according to the characteristics of the items to be sterilized. Then turn off the power or fire of the sterilizer, let it cool naturally, and then slowly open the exhaust valve to remove the remaining air before opening the lid to take out the object.

When using a pulsating vacuum sterilizer, pay attention to the following points:

1. The items to be sterilized should not be placed too tightly;

2. The cold air must be fully eliminated, otherwise the temperature in the pot will not reach the specified temperature and the sterilization effect will be affected;

3. After sterilization is completed, do not deflate or reduce pressure, otherwise the liquid in the bottle will boil violently, flush out the cork and overflow or even cause the container to burst. The lid must be opened only after the pressure inside the sterilizer drops to equal to the atmospheric pressure;

4. When sterilizing liquid, the liquid should be filled into a heat-resistant glass bottle, preferably no more than 3/4 of the volume, and the bottle mouth should be made of cotton gauze. Do not use perforated rubber or cork stoppers; steam is not allowed to be released immediately after sterilization, and the remaining air must be released only after the pressure gauge pointer returns to zero.

5. Do not put items of different types and with different sterilization requirements, such as dressings and liquids, together for sterilization to avoid losses.

6. There are now microcomputer-controlled high-pressure steam sterilizers. Just turn off the air conditioner and the instrument will automatically set the constant pressure. When the time is up, it will automatically cut off the power supply and sound the whistle. It is very convenient to use.

Recently Posted

-

How to improve the efficiency and accuracy of dental treatment and reduce patient discomfort.

November 16, 2023The dental unit is an indispensable piece of equipment in a modern dental clinic, integrating various functions and equipment to p Read More

Read More -

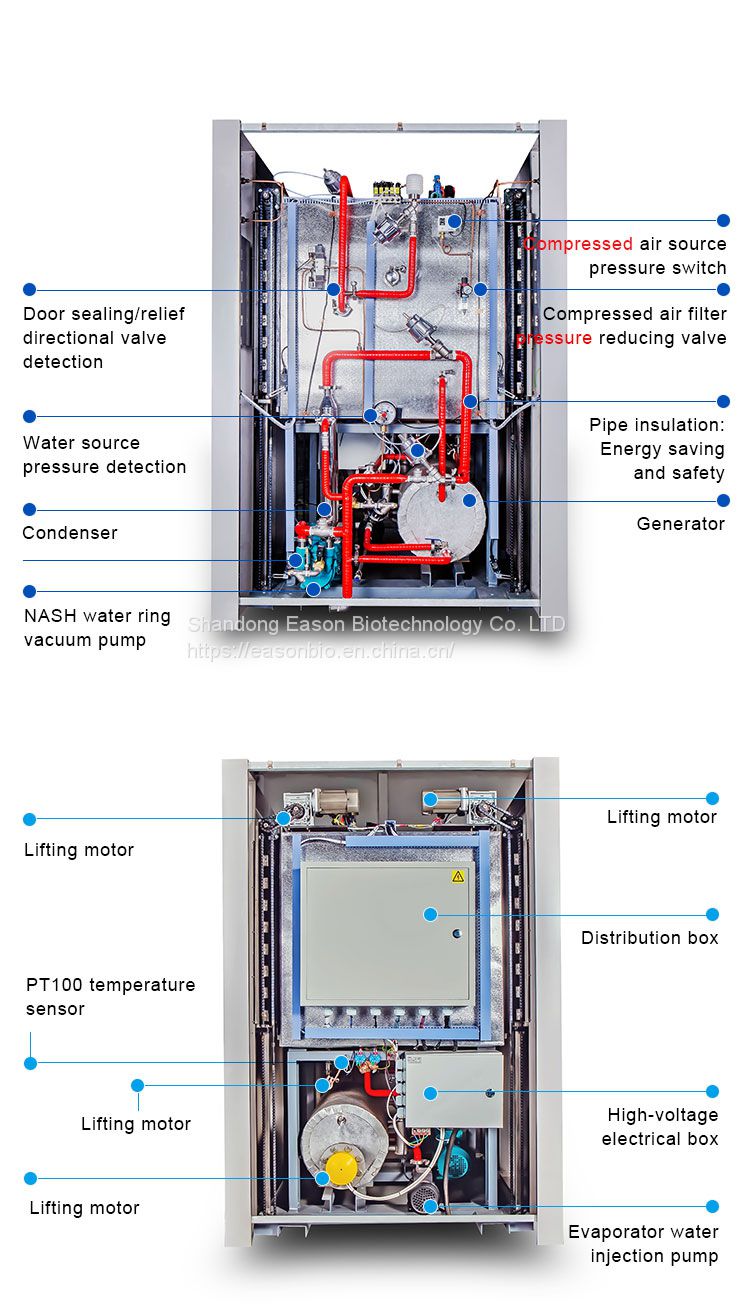

There are so many pulsating vacuum sterilizer manufacturers, which one has better quality?

November 13, 2023The pulsating vacuum sterilizer is mainly composed of a shell, a manually sealed door, a temperature display, a pressure display, Read More

Read More -

What is the sterilization medium for pulsating vacuum sterilizers?

November 13, 2023The pulsating vacuum sterilizer uses saturated steam as the sterilization medium. Through the pulsating vacuum method, the saturat Read More

Read More