There are so many pulsating vacuum sterilizer manufacturers, which one has better quality?

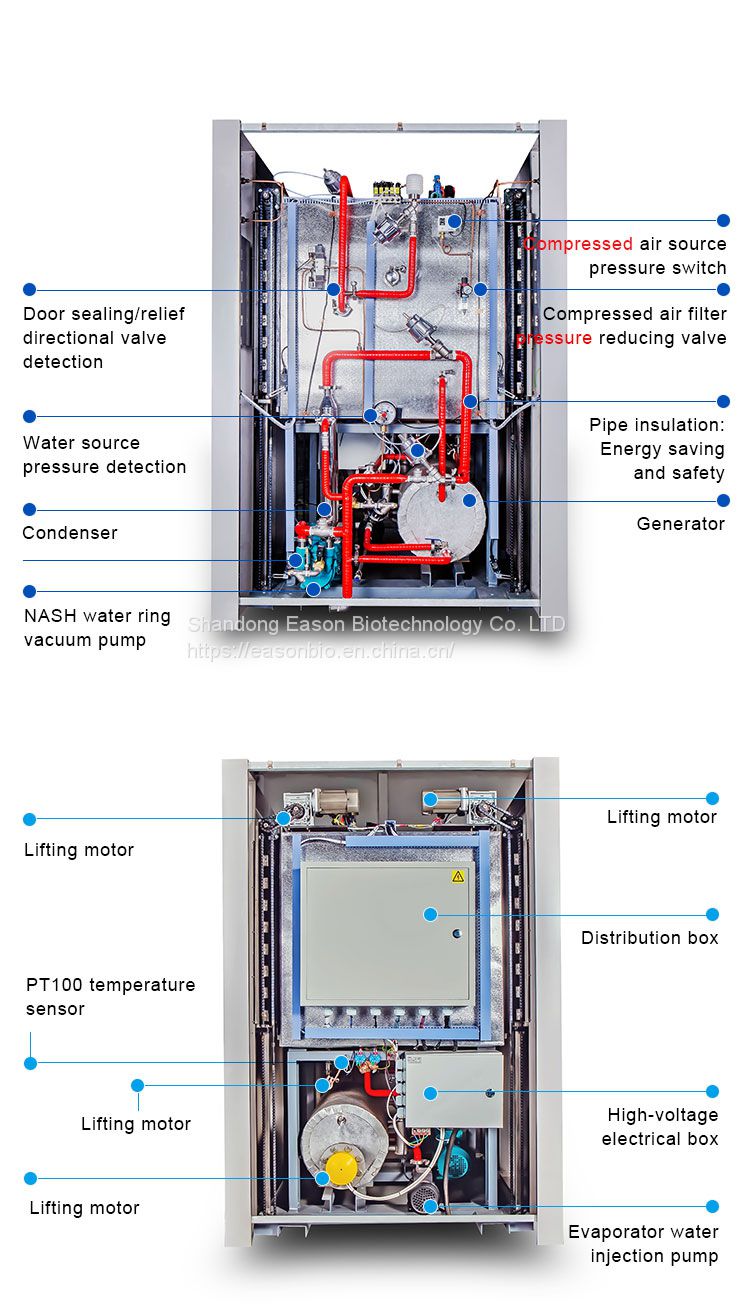

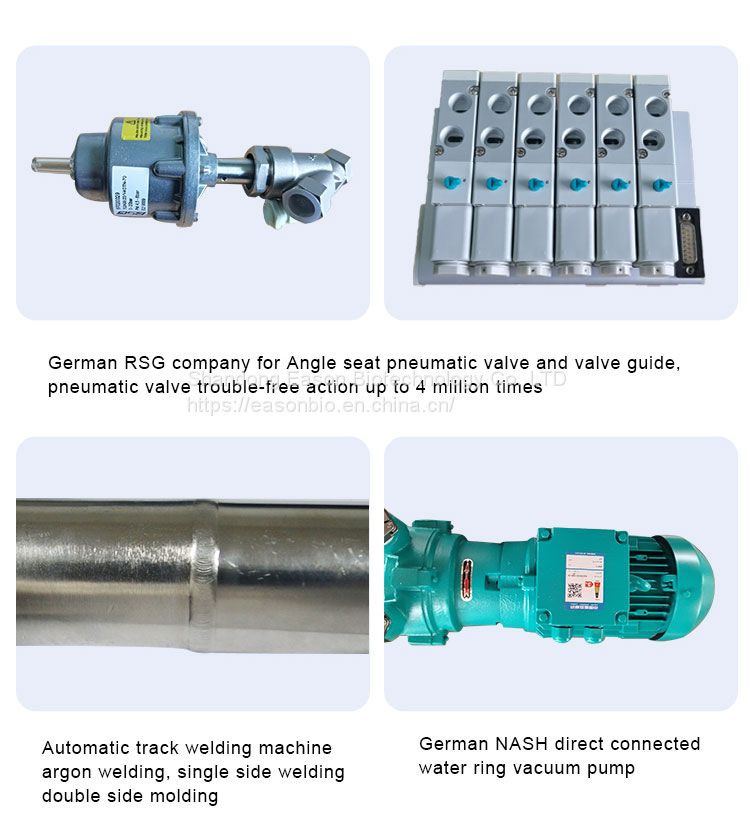

The pulsating vacuum sterilizer is mainly composed of a shell, a manually sealed door, a temperature display, a pressure display, an insulation layer, an electric heating device, and an electric heating temperature adjustment device.

The working principle of the pulsating vacuum sterilizer is to extract vacuum and fill steam into the sterilization chamber multiple times, so that after the sterilization chamber reaches a certain degree of vacuum, there will be no residual air inside the sterilizer, and then saturated steam will be filled. When the set pressure and temperature are reached, the latent heat released during the condensation of steam into water is used to kill bacteria and achieve the purpose of sterilizing the objects to be sterilized.

1. Professional and systematic program configuration, with standard sterilization programs for fabrics, instruments, rubber, rapid, liquid, and lumen, as well as auxiliary programs such as BD, PCD, and leak testing;

2. Temperature, pressure, time, operating status, fault alarm LCD display

3. Intelligent drying system, the residual humidity after drying the equipment does not exceed 0.2%, and the residual humidity after drying the dressing does not exceed 1%;

4. Built-in steam generator and microcomputer temperature control technology save time and energy;

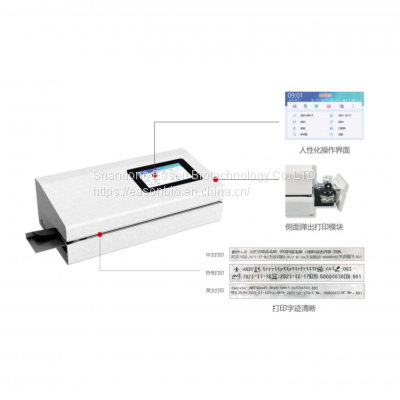

5. Configure the printer, print date, time, and process parameters;

6. Over-temperature automatic protection device, door pressure and temperature two-way safety interlock device, over-pressure automatic pressure relief safety valve, short-circuit protection, and over-voltage protection;

7. A complete four-level authority management system can effectively prevent misoperation and clearly define rights and responsibilities.

Recently Posted

-

How to improve the efficiency and accuracy of dental treatment and reduce patient discomfort.

November 16, 2023The dental unit is an indispensable piece of equipment in a modern dental clinic, integrating various functions and equipment to p Read More

Read More -

What is the sterilization medium for pulsating vacuum sterilizers?

November 13, 2023The pulsating vacuum sterilizer uses saturated steam as the sterilization medium. Through the pulsating vacuum method, the saturat Read More

Read More -

Teach you how to use a pulsating vacuum sterilizer

November 13, 2023The pulsating vacuum sterilizer is a commonly used sterilizer at present. Its operation steps are as follows: 1. The pulsatio Read More

Read More